OL2R fixtures with software

Does any of your critical machines experience continuous high levels of vibrations ?

Need to do something about it ?

Schedule a free demo to get a first-hand look at how our solutions support your business.

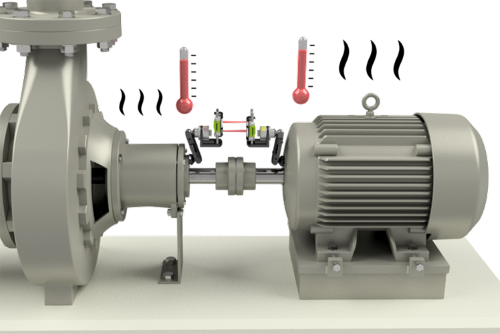

Measurements of dynamic movements are used for critical machines within industries, where large temperature differences or other disturbing factors exist. The need for dynamic measurements is indicated by a high level of vibrations. These high levels can remain even after having performed shaft alignment in cold condition.

There can be a situation where two identical machines behave differently, even though OEM recommendations have been taken into consideration, during the alignment. In order to obtain unique and exact target values, measurements in both hot and cold conditions have to be performed. Thereafter, the difference is used as machine unique target values for precision shaft alignment.

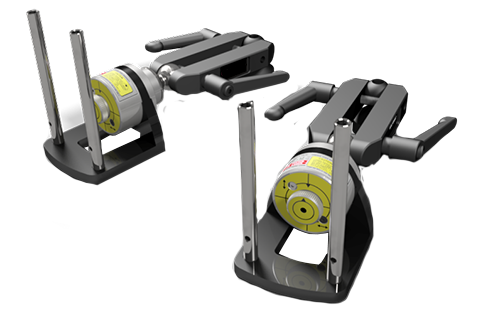

The OL2R Fixtures with case

Effortlessly navigate through our user-friendly interface, GuideU™, designed to make it a breeze to follow and understand.

Real-Time Positioning and Reporting with Acoem True Live™ Feature. Get the position of both the shafts in real-time with Acoem True Live™ feature, ensuring accurate and timely measurements.

Centralize and share your reports with your team, consolidate your plant’s alignment status, and assign alignment work orders to team members.

The Acoem NXA Pro together with the OL2R Expansion kit helps you to overcome this costly and time consuming problem by performing offline-to-running measurements. The measurements provide you with machine unique target values to be used for compensation during shaft alignment.