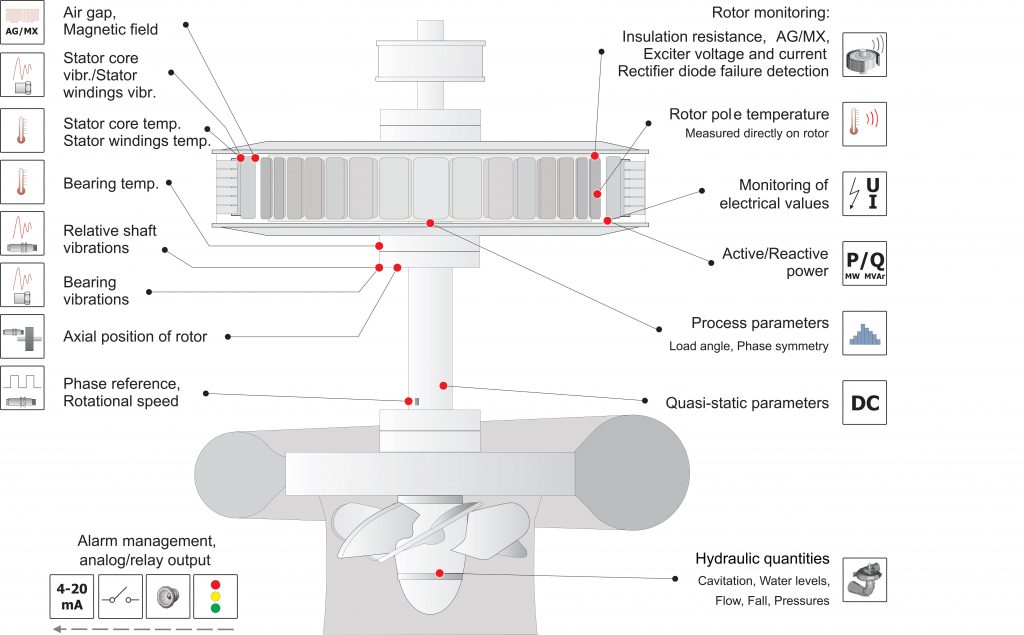

Online monitoring of shaft and bearing vibration in hydraulic turbines and generators can help identify various undesirable conditions including unbalance, misalignment, looseness, bearing wear, rubbing, hydraulic problems, electrical problems, resonance, and eccentricity of rotating parts .

The Veski CoDiS (Computerized Diagnostic System) makes it possible to monitor the status dynamically during machine operation. Machine condition issues resulting in vibration can be identified and corrective action taken well before failure. The platform can be expanded to include rotor magnetic flux as well as air gap for a more comprehensive monitoring system of the geometry and dynamic properties of hydro generators.