Gulfsiz MV-x: Black Edition

Predictive maintenance powered by artificial intelligence (AI)

Gulfsiz brings to you MV-x Black edition, the next generation of AI-enabled vibrational analysis, with real-time edge computing, provides a pathbreaking predictive tool to pinpoint the source, direction, and intensity of the vibration. It represents a fundamental shift from reactive maintenance to predictive maintenance. More importantly, it provides vibration analysis and condition monitoring users, with a seamless industry 4.0 experience.

Features

A CENTRALIZED SYSTEM

The data acquired by MV-x is automatically stored in the NEST software platform. Analysis of and access to the condition of production sites is simple: reports are accessible in just a few clicks, navigating from a map of the world to a detailed view of a machine

EASY TO DEPLOY

MV-x communicates and transfers its results in automatically and reliably to the NEST software via a secure Ethernet link. Operators can choose to use the local wired network, a Wi-Fi network, or over the Internet via a3G link, for example

INTEGRATED INTO YOUR ENVIRONMENT

MV-x can be fully integrated into your environment. Process information is retrieved directly from the PLCs, eliminating any duplication of data. The advanced indicators defined can be transmitted in order to improve process management, and maintenance management is optimized thanks to an interface with the CMMS system

SMART MONITORING

Real-time monitoring of one or more machines. Storage of measurements required for analysis: the right information at the right time. Easy analysis of complex machines through management of operating conditions. Early detection of faults on slow rotating shafts with Shock Finder

COMMUNICATION

Two-way communication with PLCs. Alerts by e-mail / logic outputs. Management of sub-optimal communication conditions (3G) for isolated machines

Accurex™ AI

Our built-in Accurex™ Artificial Intelligence can quickly provide a diagnosis of the issue, along with recommended solutions and actions, starting from the very first measurement

See our technology in action.

Schedule a free demo to get a first-hand look at how our solutions support your business.

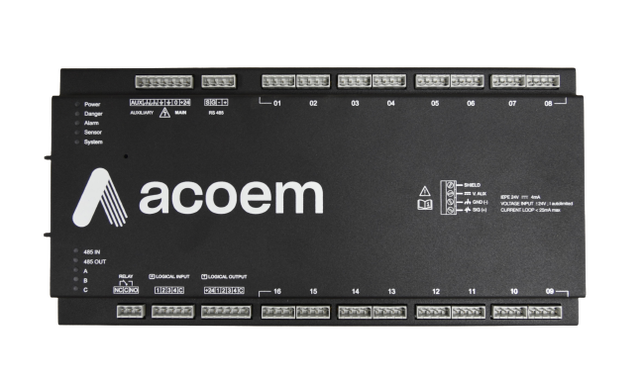

The convergence of IoT and AI

MV-x, Acoem’s signature real-time vibration monitoring system has joined the Falcon portable analyzer and the wireless Eagle to feature full connectivity with our Nest i4.0 software operating platform. Through this integration, MV-x users can benefit from the platform’s intuitive Accurex™ Artificial Intelligence (AI) driven automatic diagnostics matrix. It offers real-time data for your entire monitoring network, identifying, isolating and pinpointing machine faults to give you total oversight of your plant or factory from a single screen.

This helps improve monitoring reliability, saves time on the analysis, boosts productivity and reduces the risk associated with critical operational incidents, equipment damage or machine shutdowns.

AI-powered vibrational data for accurate insights

Gulfsiz MV-x is a multi-channel real-time wireless monitoring & diagnostics system that seamlessly integrates into the digital industry environment and delivers high-value data insights. With integrated Artificial Intelligence and the power of edge computing, it creates a secure, localized and early fault detection ecosystem, when vibrations deviate from the norm. Through instant and precise data points, it indicates the impending problem and offers remote diagnostic capabilities, empowering you to act before the event, averting downtime and its cascading consequences.

This makes the Gulfsiz MV-x a powerful predictive maintenance program and an invaluable tool for condition monitoring, which provides peace of mind to operators across diverse industrial settings. It is already a solution of choice for industrial applications around the world — including wind turbines, petrochemical plants, maritime transportation, logistics, mining, and automotive manufacturing.

Real time monitoring

Condition based maintenance advocates continuous monitoring of machinery at periodic intervals, using various vibration indicators. Acoem goes even further, as MV-x and MV-120 offer the capacity to monitor indicators in real time, ensuring:

- that no monitoring event will be missed (no gaps in data acquisition)

- responsiveness at all times: the slightest anomaly is detected in real time

- the ability to detect transient or spurious events

- Pre-trigger functions enabling the raw signal from just prior to the event.