Condition Based Monitoring - Shaft Voltage and Current Monitoring

Causes of Bearing Failures in Motors and Generators

The purpose of shaft monitoring is to indicate the presence of high levels of voltage or current on the motor or generator shaft in order to detect poor grounding shaft performance prior to bearing failures.

Poor performance of a shaft grounding brush is one of the most frequent reasons for the build-up of shaft voltage and current. During the normal operation of electrical machines, AC and DC voltages can be induced in the shaft, or created by the rotating elements of the turbine, connected to the same shaft.

Other key causes include:

- Potential applied to the shaft as result of rotor winding ground fault or spikes caused by excitation system (spikes up to 200 V).

- Asymmetry of magnetic fields caused by design, manufacturing details, rotor winding shorted turns or by large stator core faults

- Flux generated by axially magnetized turbine and generator parts

- Electrostatic effects caused by charged turbine steam or lubricants

Importance of Shaft Voltage and Current Monitoring

If shaft voltages are high enough, shaft currents can cause arching between the shaft and the bearing. The arching elevates the temperature enough to cause the metal to vaporize and result in pitting of the bearings.

Shaft voltage monitoring will also provide additional benefits that may include:

- Avoiding unexpected mechanical failures of the bearings by identifying poorly performing brushes for replacement.

- Identifying the quality of repairs or maintenance on brushes

- Prioritizing maintenance on machines in your fleet where it is most needed

Methods For Shaft Voltage and Current Monitoring

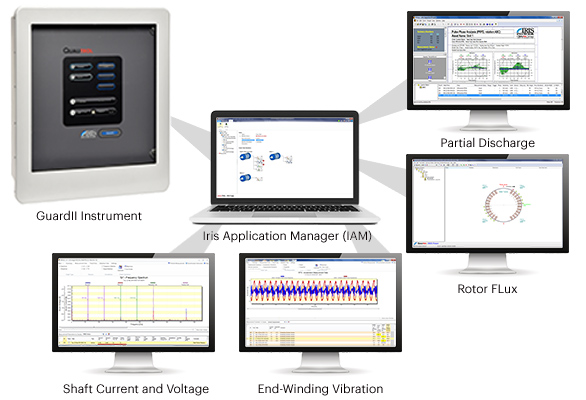

On-line shaft monitoring using the Guard II requires the permanent installation or modification of 1 or 2 voltage brushes. Shaft current and voltage signals are continuously measured by the monitor to trend and alert when grounding maintenance is required.

Installation of the GuardII can be performed without a unit shutdown, but the installation of the voltage brushes and connection to the shaft grounding brush might require a shutdown depending on the type of the brush installed.