NXA GAMESA

Shaft alignment in the wind power Industry

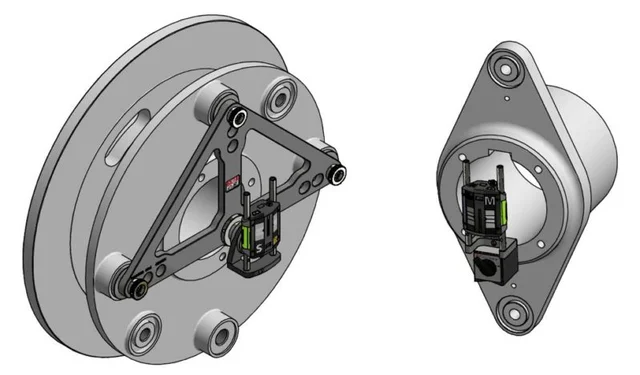

The NXA GAMESA is custom-made with firmware and fixtures designed specifically for Gamesa turbines: G80x, G90x, G114, G126, G132, G145. These precisely designed fixtures make generator-to-gearbox alignment easy inside any nacelle – safeguarding reliability and optimizing the energy efficiency of the wind turbine.

Features

Horizontal Alignment

Measures and helps correct misalignment while dual sensors maintain the true position of the shafts, even as unintended movements are experienced during the alignment process

Vertical Alignment

Same power and ease of use as the Horizontal Alignment program. The vertical alignment program is used when aligning flanged-mounted machines

Verti-Zontal

Allows for the vertical and horizontal adjustments to be made together in one pass, saving valuable time and ensuring accuracy the first time around

Machine Train

Machine Train routine simplifies the complexity of aligning multiple units with connecting shafts

Spacer Shaft

The Spacer Shaft program simplifies spacer shaft alignment by showing both ends of the spacer shaft coupling with an angle/angle display

OmniView

Changes the on-screen orientation to match what the user is actually seeing, tracking the user’s position relative to the machine being aligned

Soft Check™

Softcheck™ checks if there is a soft foot condition, i.e. when the motor is not resting firmly on all its feet

Feetlock™

This program allows the user to test alternate solutions in situations where the movable machine is base bound or bolt bound

Machine Defined Data

A set of machine configuration templates for storing data for individual machines

See our technology in action.

Schedule a free demo to get a first-hand look at how our solutions support your business.

Shaft alignment tools offer the wind power industry:

- Wireless laser heads on magnetic mounts

- Industry-leading precision

- Solutions for both rotating and non-rotating shafts

Horizontal Machines

The Gulfsiz NXA Pro is perfect for measuring horizontal alignment conditions but its real power is in helping correct misalignment. The dual sensors allow the NXA Pro to maintain the true position of the shafts, even as unintended movements are experienced during the alignment process.

Vertical Machines

The same power and ease of use found in the horizontal alignment program can be found in the vertical alignment program. The vertical alignment program is used when aligning flanged-mounted machines. The gyroscopes in the NXA Pro’s sensors allow the system to accurately measure the angles using the Tripoint Method of measurement, an industry first!

Machine Train

The NXA Pro’s machine train routine simplifies the complexity of aligning multiple units with connecting shafts. The software includes a “minimal moves” function which identifies the best reference machine to minimize the number of moves required to complete the alignment.