An app-based solution for shaft alignment.

AT-100 is an app-based alignment tool that combines integrated apps, patented technology, and easy connectivity. The AT-100 is suitable for entry-level to expert shaft alignment work, the AT-100 shaft alignment tool provides high measurement flexibility. The intuitive tool works with the shaft alignment apps on a tablet or smartphone. It is simple to use and doesn’t require any special training. The AT-100 shaft alignment solution is the result of almost 40 years of shaft alignment expertise and innovation, leveraging the latest technology to enhance your user experience.

The sensors come pre-mounted on its fixtures and pre-set to the most common setup

Digital sensor with 20 mm detector and line laser eliminates rough alignment and shorten setup time

Integrated Bluetooth for wireless communication between tablet unit and smart sensors

Task oriented Horizontal shaft alignment with mobile apps

Schedule a free demo to get a first-hand look at how our solutions support your business.

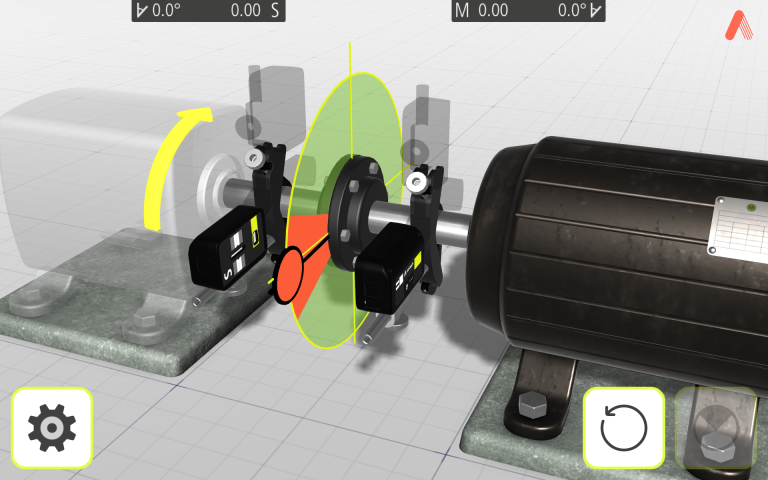

The next generation of 3D shaft alignment graphical user interfaces provides patented, customizable, icon-driven, and color-coded displays, making it easy to measure, align, document, and report on each job. Using visual, logical, and easy-to-follow steps, GuideU™ offers precise measurement and correction values and minimizes the risk of human errors.

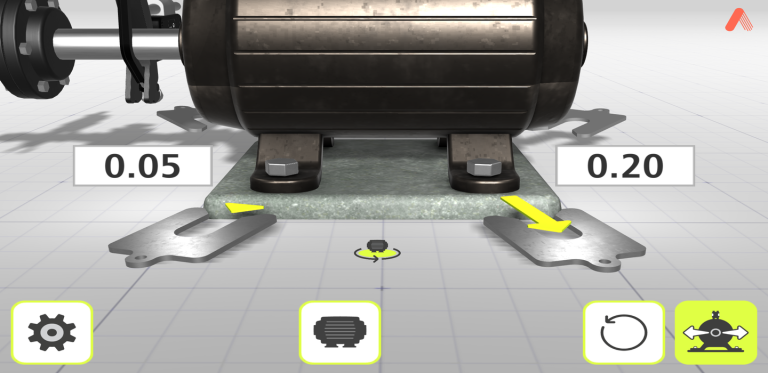

VertiZontal™ adaptive user interfaceautomatically indicates exactly how much you need to adjust your misaligned machine by adding or removing shims to the machine’s feet. This removes the need to remeasure between the vertical and the horizontal phases to correct the horizontal misalignment. This industry-first function saves time and ensures accuracy with every measurement.

Each AT-100 is delivered with the following package:

Effortlessly navigate through our user-friendly interface, GuideU™, designed to make it a breeze to follow and understand.

Real-Time Positioning and Reporting with Acoem True Live™ Feature. Get the position of both the shafts in real-time with Acoem True Live™ feature, ensuring accurate and timely measurements.

Centralize and share your reports with your team, consolidate your plant’s alignment status, and assign alignment work orders to team members.

ACOEMs adaptive user interface guides the user throughout the job in logical and easy to follow steps. It will deliver measurement and correction values based on what the system finds during the alignment process. This eliminates confusion for less-experienced users and provides ease of access throughout a measurement with the AT-100 system.